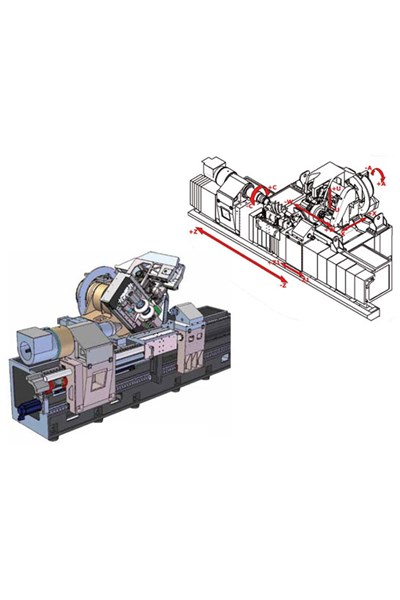

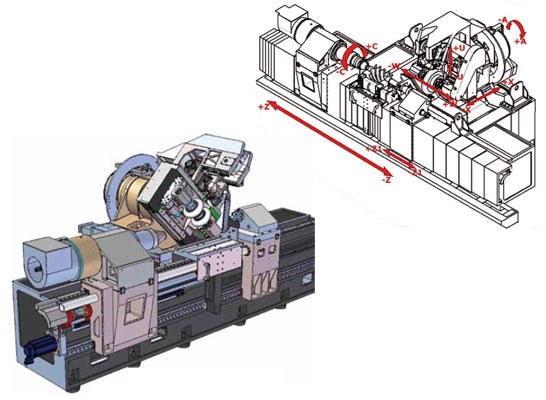

Holroyd ZENITH 400

Holroyd Helical Grinding Machine Holroyd's Gear grinding system Zenith 400 Zenith 400 introduces potential for production improvements provided by Holroyd's "next generation" Helical Profile Grinding Machine, with its high stock removal rates and aggressive semi-finishing capability - can reduce overall machine requirements in many production environments, and provide for different production rates and production accuracies to suit modern manufacturing strategies. The list of features includes: - Grinding wheel options - vitrified AIO2, vitrified CBN, plated CBN. - Accelerated and simplified set-up, enhanced by fully automated grinding wheel balancing system. - Powerful, menu-driven touch screen programming for unprecedented ease-of-use. - Holroyd's unique on-board 3D CMM component scanning probe with full automatic compensation feedback, whi ch provides high levels of accuracy. - High power, high speed spindles and advanced in-process dressing systems that maintains the accuracy of the profile while keeping the wheel in optimum condition. - Engineered for complete integration with automated parts handling systems

| Machine Operation: | CNC |

|---|---|

| Grinder Type: | Gear Grinder |

| CNC Model: | Holroyd X8 |

IS THIS YOUR COMPANY?

| Grinding Length: | 86.600" 2200.000mm |

|---|---|

| OD Max Grinding Diameter(s): | 16.530" 420.000mm |

| Grinding Wheel: |

|

||||||

|---|---|---|---|---|---|---|---|

| Wheel Head: |

|

||||||

| Workhead: |

|