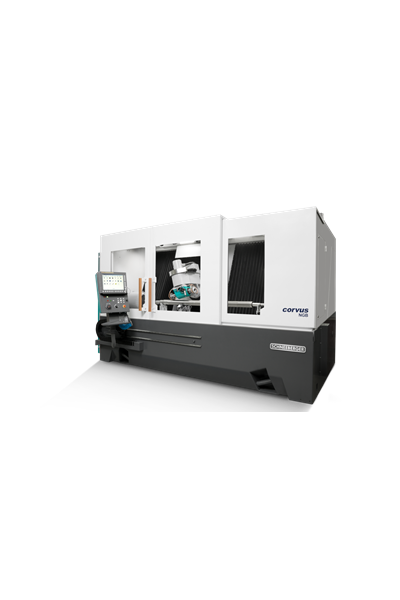

Schneeberger corvus NGB BBA

Production and regrinding of all known broaches with the 6-axis CNC grinding machine. The 6-axis CNC grinding machinecorvusBBAwith its well thought out, attractive design is the leader in broach grinding machine. It is the result of years of co-operation with broach tool manufacturers from all over the world. The CNC grinding of broach tools is possible in a single clamping grinding gullets, spiral flutes, profile, spiral profile, clearance angle, chamfers, cylindrical grinding or surface grinding and all with the highest precision. Complete processing OD and face, up to 2800 mm cutting length, diameter up to 400 mm, maximum workpiece length that can be clamped 3500 mm. With its T-slotted table, the machine envelope can accept steady rests, tailstocks and magnetic chucks. In all likelihood, the following broach tools and broach needles are ground the world over on acorvusBBA: Internal broach tool: Profile broaching tool, round, polygonal, rectangular, hexagonal, keyway, feather ke y groove External broach tool: Flat broaching tool, concave tool hard broach tool Large tool Turbine tool Helical fluting tool Broach needle for twist broaching Broach needle for hard broaching Gear rack broach needles Custom broach tools Thanks to an A-axis torque of up to 1250 Nm, tools up to 1500 kg can be produced or re-ground. Transmission manufacturers appreciate the universal nature of this machine when regrinding of gear cutting tools such as gear hobs and shaper cutters. Accessories for individual expansion of the application spectrum and increased productivity: X-stroke of 1250 mm up to optional 3100 mm Measurement system in all axes Linear motors in all axes Direct drive motor for cylindrical grinding tasks up to 1250 Nm torque Dressing unit for dressing profiles Manual or hydraulic tailstock Steady rest Magnetic chucks Collet chucks, clamping mandrels Coolant filtration system Exhaust air filter CO2 extinguishing system

| Machine Operation: | CNC |

|---|---|

| Grinder Type: | Tool & Cutter |

| CNC Model: | Fanuc 31i-B5 |

IS THIS YOUR COMPANY?

| Grinding Length: | 110.240" 2800.000mm |

|---|---|

| OD Max Grinding Diameter(s): | 15.750" 400.000mm |

| Grinding Wheel: |

|

||||||

|---|---|---|---|---|---|---|---|

| Wheel Head: |

|

| Longitudinal: | 49.210" 1250.000mm |

|---|---|

| Cross: | 15.750" 400.000mm |

| Vertical: | 15.750" 400.000mm |