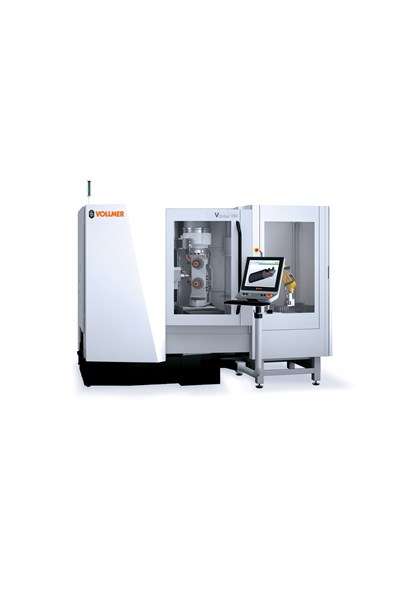

Vollmer VHYBRID 360

HYBRID TECHNOLOGY FOR EFFICIENT TOOL GRINDING AND ERODING The word "hybrid" is derived from Greek and describes something bundled, crossed or mixed. In engineering, it describes a system which skilfully combines two technologies and therefore offers the best of both worlds. The combination of sub-systems even leads to brand-new positive features. This is the case with theVHybrid360 from VOLLMER, which combines the strengths of an innovative grinding machine and a powerful erosion machine – and makes it possible to switch between both functions in next to no time. For noticeably increased efficiency and profitability in machining rotary carbide and PCD tools with diameters of up to 50 mm. Altogether that makes for two hundred per cent VOLLMER efficiency and profitability. For tool machining with its complex production tasks and high quality demands, the integration of two technologies in one machine like the VHybrid 360 can be a particularly efficient solution: Complete machining in one set-up, with minimum space requirements and maximum flexibility.

| Machine Operation: | CNC |

|---|---|

| Grinder Type: | Tool & Cutter |

| CNC Model: | NUMROTOplus |

IS THIS YOUR COMPANY?

| Grinding Length: | 14.170" 360.000mm |

|---|---|

| OD Max Grinding Diameter(s): | 1.970" 50.000mm |

| Grinding Wheel: |

|

||||

|---|---|---|---|---|---|

| Wheel Head: |

|

| Longitudinal: | 13.780" 350.000mm |

|---|---|

| Cross: | 19.700" 500.000mm |

| Vertical: | 17.700" 450.000mm |