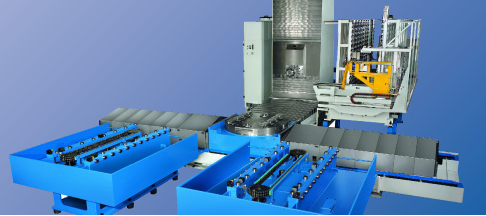

Burkhardt+Weber MCT 900

The BURKHARDT+WEBER MCT machining centers are designed for multi-task machining. In addition to all conventional machining center operations for both horizontal and vertical types, the machines are equipped to perform all vertical turning center task at up to 500 RPM. And 3-D boring and milling is available as positioning and contouring option. The system provide highpower density overall. All operations can be performed ona single machining center, with the highest flexibility with a compact foot print. And the BW-torque tables offer more: Highprecision, optimum torque/size ratio, high speed performance with low end torque capacity for milling. Oversized brake disks supply the brake torque and complement the BURKHARDT+WEBER performance standards for demanding steel and cast iron machining center tasks of milling, drilling and boring. The static turn-tools are supplied like all tools via automatic tool change from the BW tool magazine into a special turn-tool holder, also loaded aut omatically and clamped via the hydraulic BW head clamping system. All cutting forces are transferred directly into the machine frame, via the hydraulic clamping system. The exceptional large support spacing further improves the rigidity. A 5th A Axis is available and Swivel Spindle to enable both horizontal and vertical machining in a single setup is an option.

| Machine Type: | Boring Mill Machining Center |

|---|---|

| Num. of Axes: | 4 |

| Operation Type: | CNC |

| CNC Brand: | Siemens 840D sl |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 39.300(L) x 31.400(W) |

|---|---|

| Max Workpiece Weight (lbs): | 7,700 |

| Support Index Table: | None |

| Support Rotary Table: | Standard |

| Direction: | Combination |

|---|---|

| Taper: | HSK-A 100 |

| Top RPM: | 8,000 |

| HP (30 min rating): | 54.00 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 128 |

| Num. Tools Opt: | 608 |

| Tool Change Chip Time (sec): | 15.00 |

| Pallet Changer Available: | Optional |

| Num. Axes: | 4 | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Num. Axes Opt: | 5 | ||||||||||||||||||||||

| U Axis: | None | ||||||||||||||||||||||

|

|||||||||||||||||||||||