Starrag USA Inc. LX151

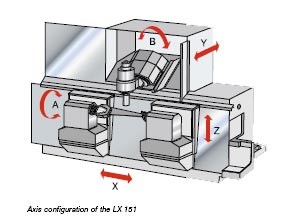

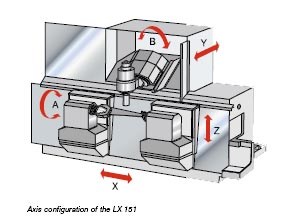

StarragHeckert LX151 5-Axis Blade Milling Machine HSC technology ensures increased performance. With the new LX machining center, StarragHeckert has successfully increased the efficiency of blade machining due to HSC technology and the machine�s inherently rigid mono-block design, ensuring the highest geometric precision and accuracy. Complete machining saves time. The true potential of the LX is not only proven by its impressive performance data during airfoil machining, but also during high precision machining of blade roots. Even longer blades can be milled in one single set up from bar stock or forging. Fixture costs are drastically reduced and efficiency of the machining process is vastly increased. Adaptive Milling improves flexibility The machining of precision forged blades places high demands on a machinin g center: In order to guarantee transition free machining, the forged contours must be accurately measured. Only then can the leading / trailing edges and snubbers be individually machined with perfect blends to existing contours. Adaptive milling eliminates inaccurate and time-consuming manual finishing operations. Machining of fan blades Precision forged workpieces, such as fan blades, are only finished in the airfoil area. Before the workpiece can be fitted, however, the leading and trailing edges, snubbers, and the transition areas must be optimized in complicated manufacturing processes. This is where the unrivalled performance of the LX shows its full potential. The efficiency of a machine tool is primarily defined by its technical concept. The innovative layout of the LX 151 offers new performance perspectives for you - the end user. Innovative Performance Turbineblade

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 5 |

| Operation Type: | CNC |

| CNC Brand: | Siemens 840D |

| CNC Brand Opt: |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 27.600(L) x 15.700(W) |

|---|---|

| Max Workpiece Weight (lbs): | 176 |

| Direction: | Vertical |

|---|---|

| Taper: | HSK-A63 |

| Taper Opt: | |

| Top RPM: | 18,000 |

| HP (30 min rating): | 38.10 |

| U Axis: | Optional |

| Tool Carrier: | Chain Magazine |

|---|---|

| Num. Tools: | 24 |

| Num. Tools Opt: | 60 |

| Tool Change Time (sec): | 8.00 |

| Num. Axes: | 5 | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | Optional | ||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||