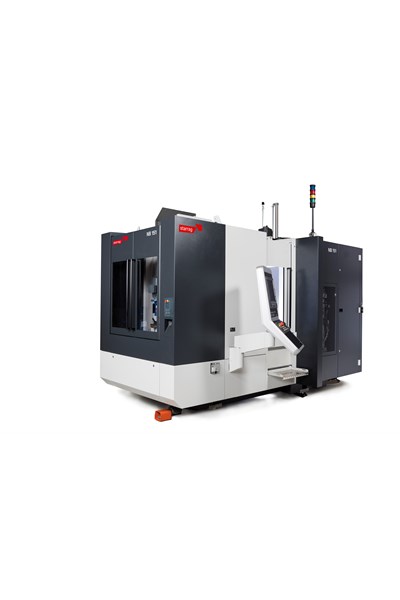

Starrag USA Inc. STC 800

StarragHeckert STC 800 Vertical Machining Center Modular machine concept The high flexibility of the STC 800 provides crucial advantages especially if quickly changing applications need to by realized safely and efficiently by using new, innovative technologies. This and ever-increasing demands in terms of quality and precision call for intelligent manufacturing concepts and maximum modularity of the entire machining center. Complex structure parts As the area of machining technology is rapidlydeveloping, the demands by innovative designers upon manufacturing experts are increasing as well. Particularly for the construction of modern aircrafts more and more complex structure parts are manufactured from aluminum and titanium. This requires a machining center with excelle nt static and dynamic qualities and high-performance milling spindles. Only these characteristics guarantee an economical high-performance machining which saves time and also simplifies the production process. The STC 800 meets these criteria to perfection. Impellers and blisks When completely machining modern impellers and blisks made of difficult-to-machine materials, precision and high availability are essential. By virtue of decades of experience in the 5-axis machining of flow surfaces we have the necessary expertise to support you in every respect, whether in the programming of our own specially developed CAM software or in the choice and development of suitable tools. General production technology The STC 800 is perfectly suited for the machining of complex workpieces, because the pieces can be machined on inclined planes as well. The machine allows the use of vertical milling heads, overlong tools and bridge-mounted tools with large diameters. Rotating axes and tilt heads work very precisely and allow the economical machining from five sides in one or several setups.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 5 |

| Operation Type: | CNC |

| CNC Brand: | Sinumerik |

| CNC Brand Opt: | Fanuc |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 31.500(L) x 31.500(W) |

|---|---|

| Table Size L x W (in.) Opt: | 39.400(L) x 31.500(W) |

| Max Workpiece Weight (lbs): | 4,400 |

| Support Index Table: | Standard |

| Support Rotary Table: |

| Direction: | Vertical |

|---|---|

| Taper: | HSK-A-100 |

| Taper Opt: | HSK-A-63 |

| Top RPM: | 15,000 |

| Top RPM Opt: | 8,000 |

| HP (30 min rating): | 49.60 |

| Tool Carrier: | Chain ATC |

|---|---|

| Num. Tools: | 60 |

| Num. Tools Opt: | 240 |

| Pallet Changer Available: | Standard |

| Num. Pallets: | 2 |

| Num. Axes: | 5 | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Num. Axes Opt: | 4 | ||||||||||||||||||||||||||

| U Axis: | None | ||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||