Danobat TCN-24

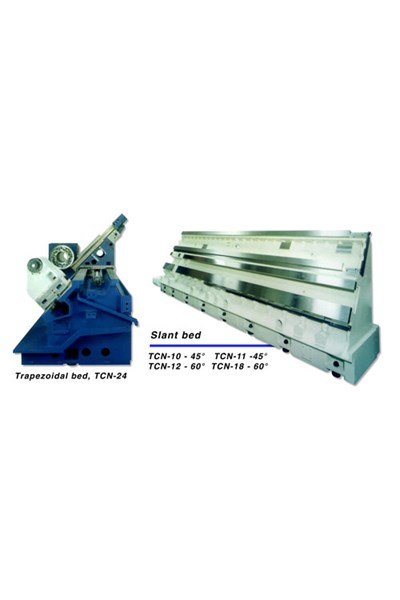

Danobat TCN-24 Series Universal Lathe Danobat Flexible, Accurate TCN-24 Series Universal CNC Horizontal Lathes The TCN-24 has an ideal machine construction with a triangular saddle and trapezoidal bed for the heavy duty turning operations. The TCN-24 is characterized by high metal removal rates including an excellent chip and coolant evacuation, perfect degrees of rigidity and heat. The TCN-24 is built to work with very heavy parts, up to nine hundred millimeters in turning diameter and short-medium production volumes. It would be manufactured in different lengths, with the possibility of incorporating various sizes of headstock and motor powers. The TCN Universal CNC Horizontal Lathes feature a one-piece heavily ribbed bed cast of Meehanite, ground and hardened guideways and telescopic metal covers that protect guideways from chips that could cause damage. The 45 degree - 60 degree slant bed design minimizes cutting force and provides exc eptional rigidity for precision, heavy cuts. Tooling is easily accessible for fast setup and part loading and unloading can be done quickly and easily with less operator fatigue. The TCN uses sub-spindles and features a Y-axis that provides the flexibility to machine complex parts with a single setup. The TCN can also be easily automated and is available with customized loading and unloading systems.

| Machine Style(s): | Universal |

|---|---|

| Spindle Direction: | Horizontal |

| Operation Type: | CNC |

| CNC Type: | Siemens 840 D |

| CNC Type Opt: | Siemens PCU 50 |

IS THIS YOUR COMPANY?

| Main Spindle Turning Diameter Max: | 35.430" |

|---|---|

| Main Spindle Turning Length Max: | 39.370" |

| Main Spindle Chuck Diameter: | 29.530" |

| Main Spindle Max Swing: | 43.410 |

| Tail Stock Quill And Body: | Standard |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | Turret | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 2 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number Of Axes Opt: | 3 | ||||||||||||||||||

| Number Of Axes Opt 2: | 3 | ||||||||||||||||||

|

|||||||||||||||||||