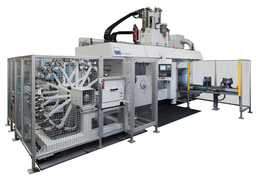

EMAG VSC 400

The VSC 400 turning machine with vertical turning technology can process round parts with a chuck diameter up to 315 / 400 mm. The advantages of the solid vertical construction of the VSC 400 lathe become apparent in the production of gears, chain wheels, couplings, components for CVTs, hinge pins, conrods, rocker arms, bearing rings or piston rings. The vertical layout of the VSC 400 lathe offers highly favorable chip flow conditions that make even dry machining an uncomplicated process.

| Machine Style(s): | Chucker |

|---|---|

| Spindle Direction: | Vertical |

| Operation Type: | CNC |

IS THIS YOUR COMPANY?

| Main Spindle Turning Diameter Max: | 13.400" |

|---|---|

| Main Spindle Chuck Diameter: | 12.400" |

| Main Spindle Chuck Diameter Opt: | 15.800" |

| Main Spindle Max Swing: | 16.500 |

| Tail Stock Quill And Body: | Optional |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | TURRET | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 2 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number Of Axes Opt: | 3 | ||||||||||||||||||

| Number Of Axes Opt 2: | 3 | ||||||||||||||||||

|

|||||||||||||||||||