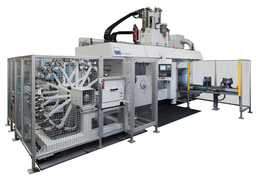

EMAG VL 8

VL 8 - CNC Turning at the Highest Level for Chucked Parts up to 400 mm in Diameter With the VL 8 vertical pick-up turning machine EMAG makes the advantages of its VL series available for large parts as well. The automation system integrated into the turning machines guarantees rapid processing, while the stable basic structure of the machine ensures top quality in turning and milling. The vertical design likewise contributes to the high machining quality, as it virtually eliminates all effects of chips generated during machining.

| Machine Style(s): | Chucker |

|---|---|

| Spindle Direction: | Vertical |

| Operation Type: | CNC |

| CNC Type: | Fanuc |

IS THIS YOUR COMPANY?

| Main Spindle Turning Diameter Max: | 15.500" |

|---|---|

| Main Spindle Turning Length Max: | 12.000" |

| Main Spindle Chuck Diameter: | 19.500" |

| Tail Stock Quill And Body: | None |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | Turret | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number Of Axes Opt: | 4 | ||||||||||||||||||

| Number Of Axes Opt 2: | 4 | ||||||||||||||||||

|

|||||||||||||||||||