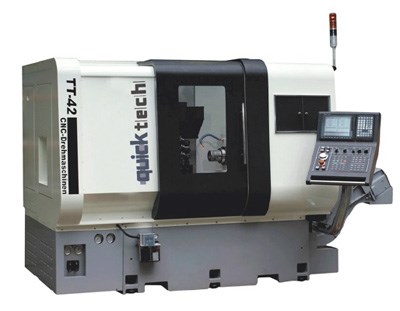

QuickTech TT-42/60

QuickTECH TT-42/60 8-Axis Turning Milling Center QuickTECH TT-42/60 CNC dual turning and milling complex lathe, available in both 42mm and 60mm bar capacities, is a high precision, high-production turning center. An all-new design, the TT-42/60 offers a reduction in the machine footprint while significantly increasing the machining capabilities and cutting capacity, and using a more stable Meehanite cast-iron frame and components. Maximum travel and feed is 140mm x 410mm x 230mm (5.51" x 16.14" x 9.05") in the main axis and 410mm x 410mm x 360mm (16.14" x 16.14" x 14.17") in the sub-axis. The QuickTECH TT-42/60 provides complete part machining, including all complex milling functions, and features eight axis and four spindles - two turning spindles, two milling spindles. A unique three-axis gang tooling system serves each spindle. The main tool post features six O.D. turning tools, four I.D. turning tools, three radial live tool heads, and three axial live tool heads. Four O.D. turning tools, five I.D. turning tools, three axial live tool heads, and three radial live tools heads is featured on the sub-tool post. Live heads are powered by a 1.3hp (2hp option) spindle motor. Live tooling is on both the main- and sub-spindle, with 12 live tools for axial and radial milling, drilling, and tapping operations, delivering a total capacity of 31 tools for complex machining tasks. A flexible tooling system is standard, with quick-change toolholders for easy changing. A mainstream tooling system is available, upon request, as well as turning blocks that are compatible with Kennametal KM and Sandvik Capto systems.

| Machine Style(s): | Bar, Chucker, Universal |

|---|---|

| Spindle Direction: | Horizontal |

| Operation Type: | CNC |

| CNC Type: | Mitsubishi M700 |

IS THIS YOUR COMPANY?

| Main Spindle Turning Diameter Max: | 3.940" |

|---|---|

| Main Spindle Turning Length Max: | 9.050" |

| Main Spindle Bar Diameter Max: | 1.650" |

| Main Spindle Bar Diameter Opt: | 2.360" |

| Sub Spindle Turning Diameter Max: | 3.940" |

| Sub Spindle Turning Length Max: | 3.940" |

| Tail Stock Quill And Body: | None |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

|||||

| Sub Spindle (Standard): |

|

| Primary Tool Carrier: | Gang Type Main | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Second Tool Carrier: | Gang-Type Sub | ||||||||

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 2 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 8 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||