+GF+ FO350 MS

AgieCharmilles FO350 MS AgieCharmilles FO350MS AgieCharmilles FO350 MS micro machining center with PC numerical control, utilizing micro-processors that allows the automatic machining of openings, from roughing to finishing, by the automatic step-by-step execution of elementary machining operations, machining cycles, part programs, and any other necessary operations between programs, such as tool changing, filling up the work tank, etc. Space saving compact design High speed Z pulse 24.6 ft/sec (7.5 m/sec) for no flushing applications with Acceleration speed of 16.4 ft/sec sq. Travers for X,Y,Z travel of 2.36 in/sec (60mm/sec) for fast tool changing, measuring time 3 sided drop tank desig n for easy access 0.00002" resolution glass scales on all axes Collision protection on all axes DP Control - Windows PC based Integrated thermo-stabilization of the table by using the circulation of the therm0-stabilized dielectric and pulsed air temperature at the same temperature as the dielectric

| Machine Type: | CNC Sinker |

|---|---|

| CNC Standard Model: | PC Based CNC |

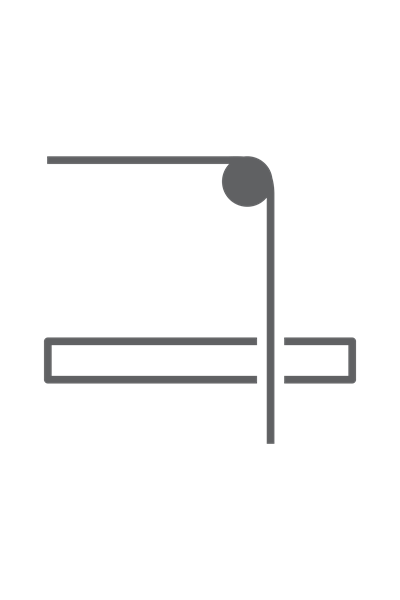

| Frame Type: | "C" |

| Submersible: | Standard |

| Filtered Particle Size: | 0 |

IS THIS YOUR COMPANY?

| Max Part Size (L x D x H): | 31.000" x 21.000" x 14.000" 787.400mm x 533.400mm x 355.600mm |

|---|---|

| Table (L x D): | 20.000" x 16.000" |

| Worktank (L x D x H): | 32.000" x 22.000" x 15.000" |

| Auto Electrode Changer: | Optional |

|---|---|

| Orbital Device: | Standard |

| Number Of Axes: | 3 |

|---|---|

| X Axis Travel: | 13.780" |

| Y Axis Travel: | 9.840" |

| Z Axis Travel: | 11.810" |