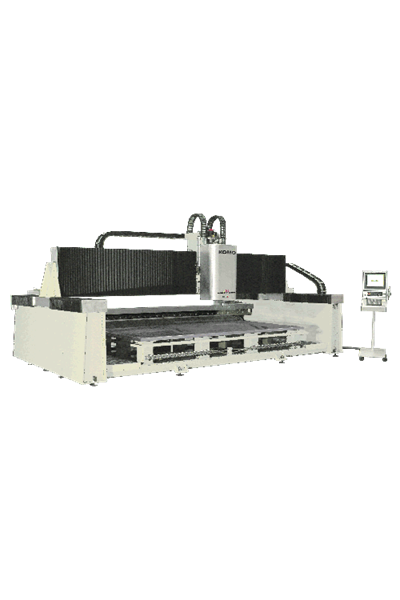

Komo Machine, Inc. Fusion VR Series

The machine frame is constructed of heavy wall, structural steel tubing. The frame has been designed and analyzed using Finite Element Analysis (FEA) to provide a rigid and stable machining platform. The frame components are stress relieved prior to machining. Machining is performed using a high precision machining center, capable of five sided machining in one set-up to insure parallelism and perpendicularity of the final product. Table / Work Surface The work surface is a precision machined aluminum high flow vacuum table sub-surface with a composite grid table that presents a modular work area for easy setup. The modular design also facilitates quick part changeover for a variety of material sizes. The aluminum construction provides superior rigidity to insure high cut quality in a variety of applications. The machine comes equipped with a high flow manifold with a 4" (102mm) diameter butterfly valve to insure high vacuum transfer from a vacuum pump to the machine table. All fitt ings and hoses necessary for the connection of the pump to the machine manifold are supplied as part of the vacuum system package, see Machine Options section. Four (4) 1" (25.4mm) diameter part location pins are included as a standard feature with every machine. The pins are located in a fixed position at 3" (76mm), 3" (76mm), 10" (254mm) and 75" (1905mm). Axis Configuration The machine is configured with a traveling table, stationary gantry design. X axis (table) motion is accomplished via pre-loaded precision rotating nut ball screw. The ball screw is driven by a digital Fanuc Alpha HVI servo motor. Fusion 524 is accomplished by a precision rack and pinion system. Y and Z axis motion is accomplished via pre-loaded precision ball screws and powered by digital Fanuc Alpha HVI servo motors. The Z axis is supported by a pneumatic counterbalance system. The system is "closed loop" to minimize air use during operation. Each axis is mounted on precision ground linear guide ways with pre-loaded precision bearing trucks. The Fanuc servo motors provide the fastest acceleration/deceleration rates in the industry. The machine is also provided with High Speed High Precision (HSHP), found standard on all models of Komo routers. This high rate of acceleration/deceleration, coupled with HSHP helps insure maximum tool life, along with reducing production times, resulting in a lower per piece part cost. Travel positioning is maintained via the controller reading 1,000,000 pulse-per-revolution absolute encoders mounted on each servo motor.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 3 |

| Operation Type: | CNC |

| CNC Brand: | Fanuc 0i-MD |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 120.000(L) x 60.000(W) |

|---|---|

| Table Size L x W (in.) Opt: | 144.000(L) x 72.000(W) |

| Support Index Table: | None |

| Support Rotary Table: | None |

| Num. Main Spindles: | 2 |

|---|---|

| Direction: | Vertical |

| Taper: | HSK 63F |

| Top RPM: | 24,000 |

| HP (30 min rating): | 18.00 |

| HP Opt: | 21.00 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 15 |

| Pallet Changer Available: | None |

| Num. Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | None | ||||||||||||||||||

|

|||||||||||||||||||