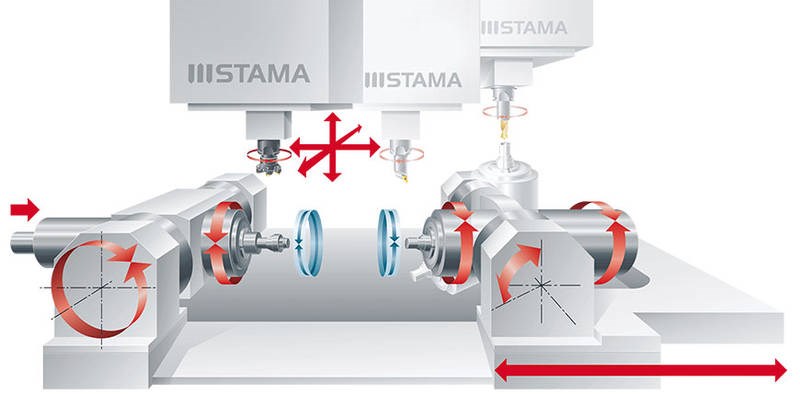

Stama MT 726

MT 7 Centers are equipped with one millingspindle and one or two turning spindle(s) in the work space. Complex workpieces can be precisely milled and turned on all six sides in two clamping positions - From bars, blanks and semi-finished products. High flexibility in single part and series manufacturing: Standard clamping, large tool magazine and optimal operator ergonomics ensure short changeover times. Small volume manufacturing, with minimal set up time. M 7 Centers offer the same benefits when just milling complex workpieces.

| Machine Style(s): | Bar, Chucker, Universal |

|---|---|

| Spindle Direction: | Horizontal |

| Operation Type: | CNC |

| CNC Type: | Fanuc 31 i-A5 |

| CNC Type Opt: | Siemens 840D sl |

IS THIS YOUR COMPANY?

| Main Spindle Turning Diameter Max: | 2.560" |

|---|---|

| Main Spindle Turning Length Max: | 4.720" |

| Main Spindle Chuck Diameter: | 4.000" |

| Main Spindle Bar Diameter Max: | 2.550" |

| Tail Stock Quill And Body: | Optional |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | ATC | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 4 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||