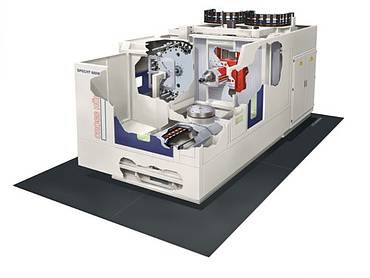

FFG MAG SPECHT 500

The Cross Huller SPECHT® Series Machining Centers and Boring Machines feature 3, 4, 5, and 6-axis types with travelling "W" axis table instead of spindle, single or twin spindles, and many other configurations. The series is especially productive in many automotive and other precision, and complex applications. Higher productivity / reduction of cycle time by direct loading (omission of travelling distance of the W-axis) and by assembling the rotary table (designed as A-axis or B-axis) in two positions (with shorter tools the rotary table is closer to the spindle) Higher accuracy on all machining sequences which do not need the jig boring accuracy of a W-axis machine. This is achieved by the firmly assembled fixture. Compact, space-saving design by omission of W-axis. "Direct" loading into the fixture (shorter than Specht 500 W). Due to a lowered operating height of the tool magazine interfering operating platforms can be left out. Newl y designed disc magazine for up to 29 tools with a maximum length of 320 mm. It is not necessary to set up the machine bed with a 5-point support in order to guarantee the geometric features. The static weight is supported by 3 fixation points in the basic position (instead of 8 fixation points at the former SPECHT machines) Optional A or B axis allow simplified part flow since the parts can always remain in the same position. Clean working area due to the air flow that is directed from top to bottom (instead of air flow from bottom to top) Reduced coolant demand due to optional chip conveyor spiral. Can be used for many machining tasks in dry machining. Please note!!! The SPECHT 500 D is not a "purebred" dry machine.

| Machine Type: | Boring Mill Machining Center |

|---|---|

| Num. of Axes: | 4 |

| Operation Type: | CNC |

| CNC Brand: | Siemens 840D |

| CNC Brand Opt: | Bosch Rexroth MTC200 |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 23.600(L) x 23.600(W) |

|---|---|

| Max Workpiece Weight (lbs): | 1,320 |

| Num. Main Spindles: | 2 |

|---|---|

| Direction: | Horizontal |

| Taper: | HSK-A-63 |

| Taper Opt: | HSK 100 |

| Top RPM: | 16,000 |

| HP (30 min rating): | 33.30 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 40 |

| Num. Tools Opt: | 100 |

| Tool Change Chip Time (sec): | 2.80 |

| Pallet Changer Available: | Standard |

| Num. Pallets: | 2 |

| Num. Pallets Opt: | 4 |

| Num. Axes: | 4 | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Num. Axes Opt: | 5 | ||||||||||||||||||||||||||

| U Axis: | None | ||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||