1010 W. Fullerton Avenue

Unit E

Addison, IL 60101 US

331-979-0954

kern-microtechnik.com

IS THIS YOUR COMPANY?

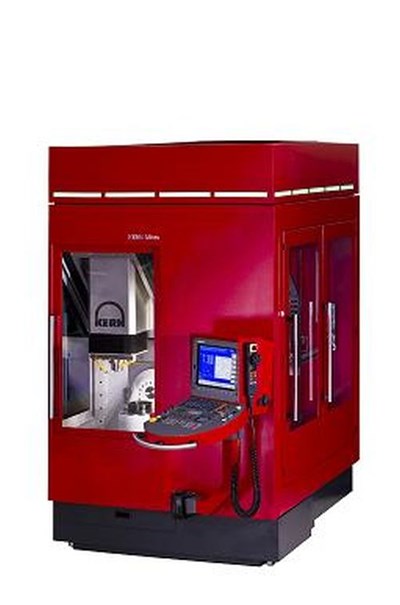

Models Offered By Kern Precision Inc.

Kern Precision Inc. Distributors

| DISTRIBUTOR | CITY | STATE |

|---|---|---|

| Precision Technologies | Victor | NY |