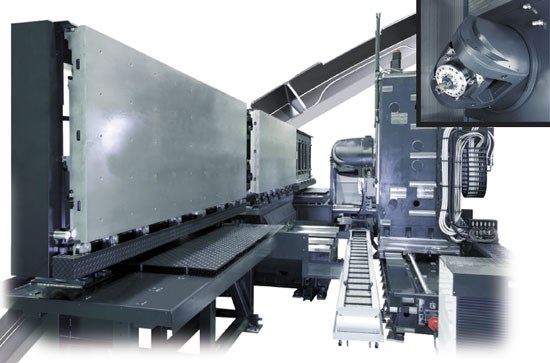

Makino T4

Makino's T4 five-axis horizontal machining center dramatically increases titanium milling efficiency, combining lean manufacturing methods and increased metal removal rates for aerospace applications. It is specifically designed for the production of large titanium and titanium alloy aerospace parts such as edge frames, pylons and bulkheads. The T4 includes several key elements for efficient titanium machining, including an Active Dampening System, rigid construction for enhanced performance, a high torque, high powered spindle, and a high pressure, high flow coolant system for increased speed and productivity. The machine's HSK-A125 spindle provides higher torque, horse power, and clamping force than all predecessors. It's compact design combines the latest induction motor technology with twin inverter drive technology for higher torque (740ft-lbs, 133HP continuous; 1,100ft-lbs, 200HP peak). The spindle is supported by roller bearings to ensure high rigidity, which keeps the energy loss to one-half that of conventional gear-driven spindles. The spindle delivers a maximum cutting force of 20,000N and has a maximum speed of 4,000RPM. The A and C-axes increase part accessibility with a +/-110 degree A-axis rotation and a 360 degree continuous C-axis rotation.The T4 can be equipped with an automatic pallet changer system for continuous operations, eliminating cost.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 5 |

| Operation Type: | CNC |

| CNC Brand: | Fanuc S30i + Pro 5 |

| Table Size L x W (in.): | 157.500(L) x 59.100(W) |

|---|---|

| Max Workpiece Weight (lbs): | 11,022 |

| Direction: | Horizontal |

|---|---|

| Taper: | HSK-A125 |

| Top RPM: | 4,000 |

| HP (30 min rating): | 133.00 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 120 |

| Num. Tools Opt: | 180 |

| Tool Change Time (sec): | 20.00 |

| Tool Change Chip Time (sec): | 40.00 |

| Pallet Changer Available: | Optional |

| Num. Axes: | 5 | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | None | ||||||||||||||||||||||

|

|||||||||||||||||||||||

IS THIS YOUR COMPANY?