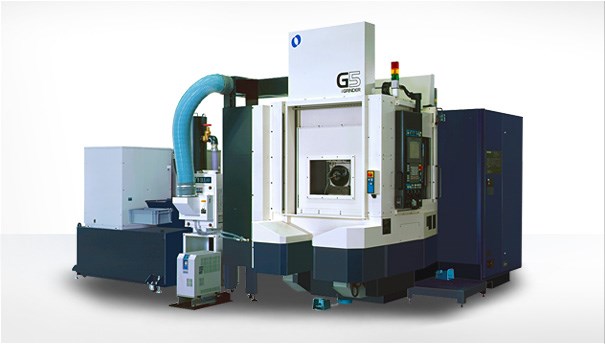

Makino G5

Makino G5 5-Axis Horizontal Grinding and Milling Center The G5 5-axis horizontal machining and grinding center is a single-platform solution for grinding, drilling and milling of aerospace blades, vanes, turbine disks and other complex grinding applications. Its multifunctional configuration paired with 5-axis capabilities enables aerospace manufacturers to eliminate setups, work in process, stack-up errors, and fixture costs. It also simplifies the manufacturing process with NC-controlled intermittent dress. TheG5 5-axis horizontal machining center employs a 12,000-rpm HSK-63A spindle and X, Y, and Z travels of 20.5', 22", and 23.6". A unique two-axis Programmable Coolant Nozzle (PCN) lets the G5 accommodate variations in wheel diameter and changes in cutting direction while maintaining ideal coolant flushing conditions. It also allows for intermittent rotary dressing, an NC-controlled, electrically powered feature that trues the wheel to reestablish profile geometry on the cutting wheel. Combined use with the standard 60-tool capacity automatic tool changer enables continuous operation to be performed, maximizing throughput.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 5 |

| Operation Type: | CNC |

| CNC Brand: | Professional 5 |

| CNC Brand Opt: |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 9.840(L) x 9.840(W) |

|---|---|

| Max Workpiece Weight (lbs): | 264 |

| Direction: | Horizontal |

|---|---|

| Taper: | #40 |

| Taper Opt: | HSK-A63 |

| Top RPM: | 12,000 |

| HP (30 min rating): | 33.00 |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 60 |

| Num. Tools Opt: | 180 |

| Tool Change Time (sec): | 0.90 |

| Tool Change Chip Time (sec): | 2.19 |

| Num. Axes: | 5 | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | None | ||||||||||||||||||||||

|

|||||||||||||||||||||||