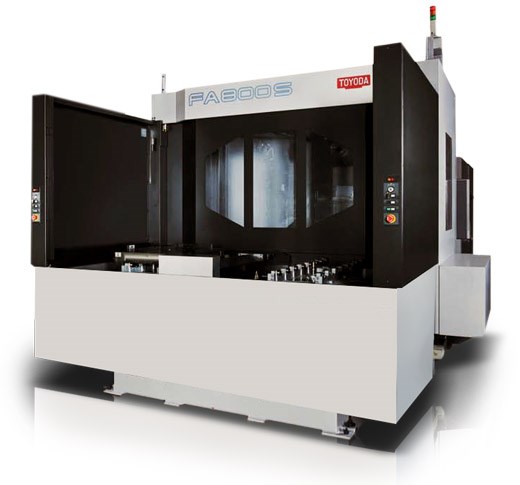

Toyoda FA800S

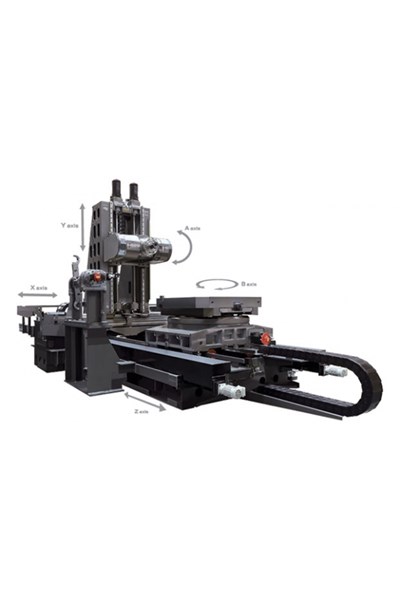

The FA800S Combines speed and power for large and heavy workpieces. Special pallet design for heavy loads. Toyoda's Cutting Machine Division provides a range of horizontal spindle machining centers. From 40-taper machines in 1969 ipm feeds (achieved with unique hybrid roller boxways) to 50-taper production platforms with work areas of 65 x 55 x 45 inches. All are available with a variety of high-speed spindles, high-torque direct drive or geared head spindles, tool magazines, fourth or fifth axis tables, and a host of mechanical and control options.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 4 |

| Operation Type: | CNC |

| CNC Brand: | Fanuc 31i |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 31.500(L) x 31.500(W) |

|---|---|

| Max Workpiece Weight (lbs): | 5,500 |

| Support Index Table: | Standard |

| Support Rotary Table: | Standard |

| Direction: | Horizontal |

|---|---|

| Taper: | # 50 |

| Top RPM: | 6,000 |

| Top RPM Opt: | 15,000 |

| HP (30 min rating): | 40.00 |

| HP Opt: | 60.00 |

| U Axis: | Optional |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 60 |

| Num. Tools Opt: | 384 |

| Tool Change Time (sec): | 2.00 |

| Tool Change Chip Time (sec): | 7.90 |

| Pallet Changer Available: | Standard |

| Num. Pallets: | 2 |

| Num. Axes: | 4 | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Num. Axes Opt: | 5 | ||||||||||||||||||||||

| U Axis: | Optional | ||||||||||||||||||||||

|

|||||||||||||||||||||||