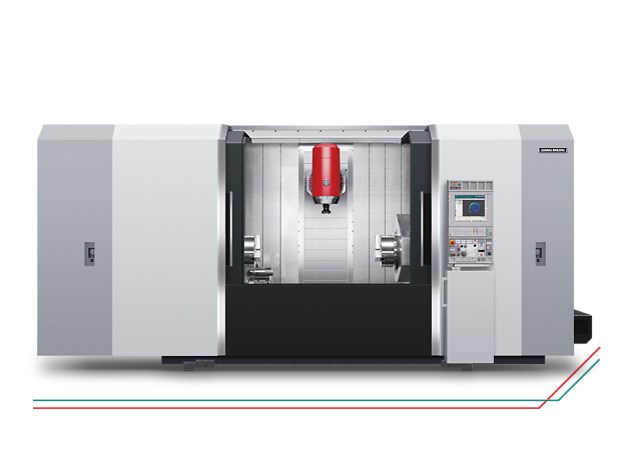

DMG MORI USA, Inc. NT 5400 DCG

Simultaneous 5-axis machining of complex parts with the direct drive motor (DDM) installed in the B-axis B-axis rotation range ±120° Digital tailstock equipped as standard Movable + swivel operation panel for comfortable setups High-speed, high-accuracy machining achieved by NT series original Box in Box structure and Driven at the Center of Gravity Tool spindle: Higher cutting performance and machining accuracy with 2-face contact Capto specification ORC (Octagonal Ram Construction) as a solution for heat control to ensure high-speed, high-accuracy feed Power-saving setting and reduction in consumption of lubricating oil

| Machine Style(s): | Bar, Chucker |

|---|---|

| Spindle Direction: | Horizontal |

| Operation Type: | CNC |

| CNC Type: | MAPPS IV |

IS THIS YOUR COMPANY?

| Main Spindle Turning Diameter Max: | 36.200" |

|---|---|

| Main Spindle Turning Length Max: | 75.600" |

| Main Spindle Bar Diameter Max: | 4.100" |

| Tail Stock Quill And Body: | None |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Second Tool Carrier: | |||||||||

| Max Tools: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 8 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||