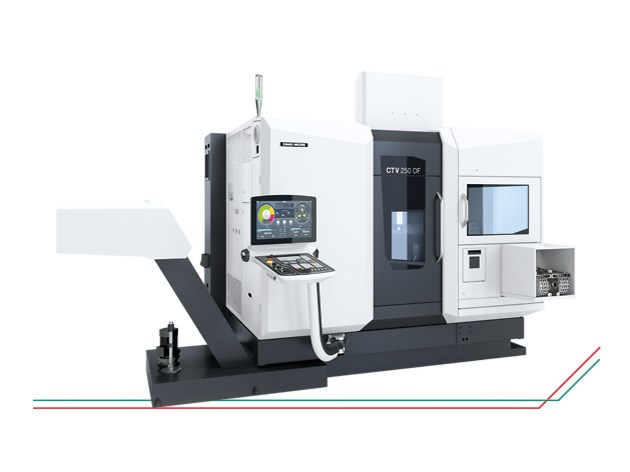

DMG MORI USA, Inc. CTV 250 DF

Additional Capto C5 mount for multiple tool with up to four cutting edges Optional: mini turret with 8 tool stations (not available with Capto C5 recording) Swivel range of the swing arm + 105 / -45 ° Powerful machining with 6,000 rpm, 28.2 hpand 166ft lb Highest stability thanks to the use of the largest spindle bearings in their class: Ø 3.9of the front bearing Highest accuracy with Consistent management, documentation and visualization of order, process and machine data Compatible with PPS and ERP systems. Can be networked with CAD / CAM products. Holistic analysis and control of the machine due to the exclusive apps Condition Analyser and Performance Monitor Shortest chip-to-chip time through double-track automation Use of inserts or pallets in the towing frames for the position-oriented machining Integration of further processes such as measuring, cleaning, deburring, labeling, etc.

| Machine Style(s): | Chucker |

|---|---|

| Spindle Direction: | Vertical |

| Operation Type: | CNC |

IS THIS YOUR COMPANY?

| Main Spindle Turning Diameter Max: | 8.700" |

|---|---|

| Main Spindle Turning Length Max: | 7.900" |

| Main Spindle Chuck Diameter: | 10.200" |

| Tail Stock Quill And Body: | None |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | Turret | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number Of Axes Opt: | 4 | ||||||||||||||||||

| Number Of Axes Opt 2: | 4 | ||||||||||||||||||

|

|||||||||||||||||||