Makino EDNC15

The EDNC15 is design to accommodate large, heavy work pieces while maintaining the highest level of precision, and makes use of a stationary work table design and minimizes the machine foot print by integrating di-electric reservoir into the base casting of the machine. Loading and unloading of large parts is made easy using the 4-side rise and fall work tank that drops below the work table height, and optimal machining speed with low electrode wear is achieved using the high speed HS-Rib Z-Axis that attains jump speeds of up to 20m/min. The Hyper-i control empowers operators of all skill levels to achieve productive results with fast cycle times using the advanced SuperSpark™ IV and HyperCut technologies. The Hyper-i control features an intuitive large high definition 24” touch screen interface that enables higher-level capabilities with the embedded on-machine support of the EDM Assist digital manuals and practical E-Tech Doctor advanced help function.

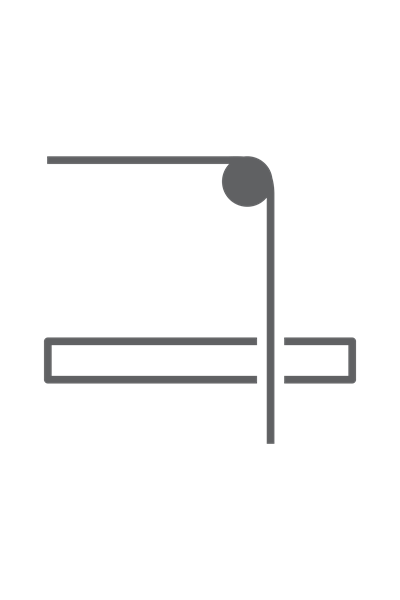

| Machine Type: | CNC Sinker |

|---|---|

| Frame Type: | Bridge |

| Submersible: | None |

IS THIS YOUR COMPANY?

| Table (L x D): | 78.740" x 39.370" |

|---|---|

| Worktank (L x D x H): | 98.400" x 55.120" x 31.500" |

| Auto Electrode Changer: | Optional |

|---|

| Number Of Axes: | 3 |

|---|---|

| X Axis Travel: | 59.000" |

| Y Axis Travel: | 27.600" |

| Z Axis Travel: | 19.700" |

| C Axis Available: | Standard |