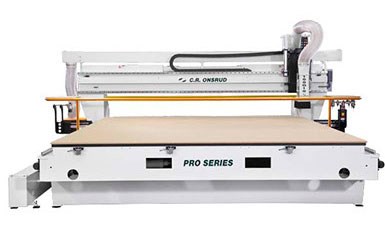

C.R. Onsrud Inc. 98RH18 - Roller Hold-Down Series

C.R. Onsrud RH Series (Roller Hold Down) CNC routers provide the ultimate in flexibility for CNC routing – single sheet / stacked sheet, small part / large part, rollers engaged / disengaged – delivering the capability and flexibility of having multiple CNC machines for the cost (and footprint) of one. The rugged, fixed bridge design of our RH Series machines feature 2 fully automated rollers on each side of the cutting spindle envelope, which engage the sheet material to maintain firm contact with the router’s table. The RH design makes this machine perfect for holding down warped stock, multiple stacked sheets, or when machining narrow, low surface area parts. Each roller offers full, independent control over regulating holding pressure, which serves to prevent premature wear and tear (which may occur on other brands) due to continuous slamming of rollers into the table and/or raw material. It is important to understand the rollers are designed to supplement (not replace) the standar d vacuum holding, creating optimal performance and maximum speed without moving parts. The RH Series is an established CNC workhorse in our industry and we continue to add the options and improvements needed by our customers to keep them outperforming the competition! This machine is at the top of its class, and truly one to be reckoned with for its extremely powerful multi-sheet, nested-base capabilities. In addition to the superior cutting speed, and accuracy it delivers, the rigid fixed bridge CNC machine can become the backbone of a totally automated production line, offering even greater efficiencies to your operation. Material handling, part identification, pusher sweeper, debris collection, automated infeed/outfeed tables, robotic arm loading and more are all components which deliver time-savings and world-class production power when mated to the RH Series by C.R. Onsrud.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 3 |

| Operation Type: | CNC |

| CNC Brand: | FANUC |

| CNC Brand Opt: | OSAI |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 48.000(L) x 96.000(W) |

|---|---|

| Support Index Table: | None |

| Support Rotary Table: | None |

| Direction: | Vertical |

|---|---|

| Taper: | HSK 63F |

| Top RPM: | 24,000 |

| HP (30 min rating): | 18.00 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 12 |

| Pallet Changer Available: | None |

| Num. Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | None | ||||||||||||||||||

|

|||||||||||||||||||