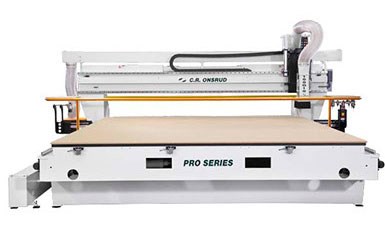

C.R. Onsrud Inc. F148CH - 5-Axis Compact High Mill Series

The newly redesigned Compact High Rail Series CNC machining center is based on a heavy, one-piece, engineered (thick-walled) steel base with internal steel reinforcements, thus forming a machine bed engineered to handle the extreme weights of large blocks of materials you'll be throwing at it. The massive moving bridge provides over three foot of bearing spacing which offers substantial leverage over the part. Spanning the stationary support walls (and supported by heavy-gauge steel), the dual ball-screw drive mechanisms deliver smooth, fast, precise, and back-lash free motion of the bridge as well. All electronics and mechanical drives are located completely outside of the machining envelope to prevent potential contamination associated with either wet or dry machining. The addition of internal perimeter walkways and optional retractable roof bellows allow for ease of material loading and part unloading. The redesign results in a roomier cutting envelope – more power, rigidity and a ccuracy – and the ability to machine large block or plate raw materials within an enclosure. The new 5-Axis Compact High Rail by C.R. Onsrud is a serious CNC machine for serious manufacturing applications.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 5 |

| Operation Type: | CNC |

| CNC Brand: | OSAI 10/510 |

| CNC Brand Opt: | FANUC |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 84.000(L) x 144.000(W) |

|---|---|

| Support Index Table: | None |

| Support Rotary Table: | None |

| Direction: | Vertical |

|---|---|

| Taper: | HSK 63F |

| Top RPM: | 24,000 |

| HP (30 min rating): | 15.00 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 15 |

| Pallet Changer Available: | None |

| Num. Axes: | 5 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | None | ||||||||||||||||||

|

|||||||||||||||||||