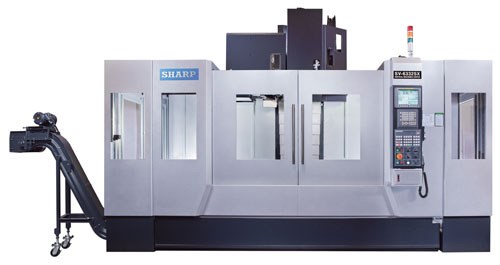

Sharp-CNC SV-6332

The Sharp SV-6332 uses a rigid “C” frame design using hardened and ground box ways. Structural components are made fromMeehanite casting with internal ribs supportingeach section. Precision hand scraping of each section provides optimalalignment assuring long term accuracies. The CAT #40 taper spindle is equipped with a 25 hp, 12,000 rpm. Coolant through spindle is prepped for 20 bar.The Fanuc 0i-MD control with color LCD is used along with all Fanuc motors and drives. For operator convenience, a remote jog handle is standard.Valuable standard accessories include convenient pull out coolant tank, flood coolant, halogen work light and auto-lubrication system.

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 3 |

| Operation Type: | CNC |

| CNC Brand: | Fanuc 0i-MD |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 78.800(L) x 33.000(W) |

|---|---|

| Max Workpiece Weight (lbs): | 4,840 |

| Support Index Table: | None |

| Support Rotary Table: | Optional |

| Direction: | Vertical |

|---|---|

| Taper: | CAT #40 |

| Top RPM: | 12,000 |

| HP (30 min rating): | 25.00 |

| U Axis: | None |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 30 |

| Tool Change Time (sec): | 1.50 |

| Tool Change Chip Time (sec): | 2.40 |

| Pallet Changer Available: | Optional |

| Num. Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Num. Axes Opt: | 4 | ||||||||||||||||||

| U Axis: | None | ||||||||||||||||||

|

|||||||||||||||||||