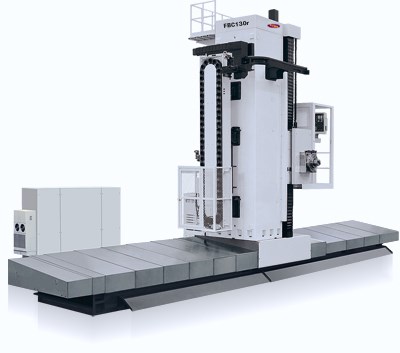

SMTCL FBC130r

The FBC Series floor type boring and milling machines uses a single-column, side-mounted headstock design. The column and saddle travel horizontally along the bed guideways. The headstock travels vertically on the column guideways. Siemens AC servo motors are installed on all axes. The X-axis adopts double-motor, double-gear and rack drive technology, which improves the driving force of the X-axis and eliminates backlash more effectively over traditional single-motor, double-gear technology. The two motors are synchronized and in slight opposition to each other in a way that is controlled electronically by the CNC and drives to remove backlash. The Y-axis uses the double-motor and double ball screw drive system. The Z and W axis use single pre-loaded ball screw drive system. X, Y, and Z (Ram) axes use closed system constant flow hydrostatic guideways, which give high performance, low vibration, and retain high precision long term. The W-axis adopts western-made linear guideways as auxi liary ways, and is equipped with a linear encoder to make the extension and retraction of the spindle a full-loop controlled axis. A, Y, and Z axes all have Heidenhain linear encoders for feedback providing closed loop control, which improves positioning accuracy. The headstock incorporates a large cross-section CNC-controlled ram, which contains a CNC-controlled boring spindle within. This aids in deep-hole and surface machining. The ram uses double hydraulic cylinders with proportionate valve system, and together with the CNC and drive mechanisms of the headstock, compensate for gravitational droop as the ram extends from the headstock. The spindle and ballscrew supports al adopt western-made bearings.

| Machine Type: | Boring Mill |

|---|---|

| Num. of Axes: | 4 |

| Operation Type: | CNC |

| CNC Brand: | Siemens 840D |

| CNC Brand Opt: | Fanuc 18i |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 70.800(L) x 63.000(W) |

|---|---|

| Table Size L x W (in.) Opt: | 78.000(L) x 63.000(W) |

| Max Workpiece Weight (lbs): | 22,000 |

| Support Index Table: | None |

| Support Rotary Table: | Optional |

| Direction: | Horizontal |

|---|---|

| Taper: | #50 |

| Top RPM: | 1,500 |

| HP (30 min rating): | 68.00 |

| U Axis: | Optional |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 40 |

| Num. Tools Opt: | 60 |

| Pallet Changer Available: | None |

| Num. Axes: | 4 | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Num. Axes Opt: | 5 | ||||||||||||||||||||||

| U Axis: | Optional | ||||||||||||||||||||||

|

|||||||||||||||||||||||