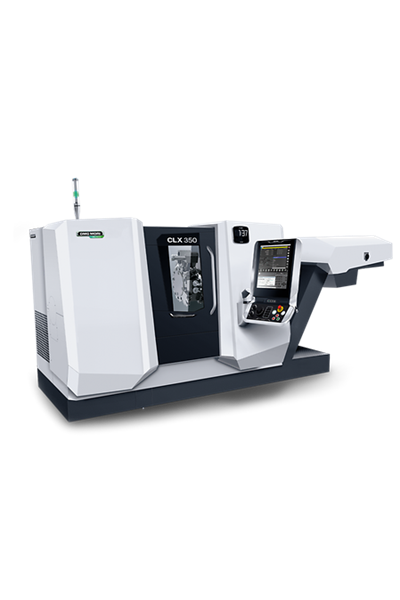

DMG MORI USA, Inc. GM 20-6

Component diameter up to 1 in. High cutting efficiency due to macimum speeds up to 5,000 rpm Adjustable minimum cycle time Maximum rigidity through a machine construction based on a frame or portal design to minimize distortion during machining Optimal damping properties through machine bed, main spindle and front-working tool carrier construction and the overhead bracing Maximum stability through machining of workpieces from the front (no angle tools required) and guidance of the front-working tools on the central block Oil cooling of all spindle bearings Independent, stepless adjustment of working stroke in all stations Four compound-rest slides for radial or straight turning

| Machine Style(s): | Bar, Universal |

|---|---|

| Spindle Direction: | Horizontal |

| Operation Type: | CNC |

| CNC Type: | Siemens PLC |

IS THIS YOUR COMPANY?

| Main Spindle Turning Diameter Max: | 1.000" |

|---|---|

| Main Spindle Turning Length Max: | 7.100" |

| Main Spindle Bar Diameter Max: | 1.000" |

| Tail Stock Quill And Body: | None |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 18 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||