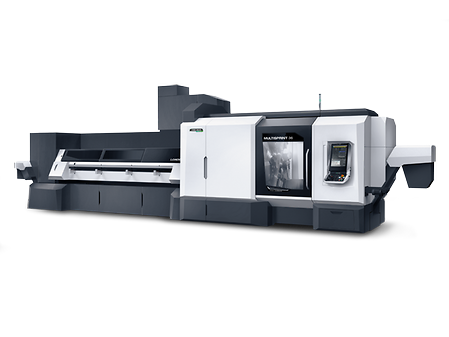

DMG MORI USA, Inc. MULTISPRINT 36

Driven tools and Y-axis machining in all positions Chuck machining and Swiss-type kit for long turning in one concept Advanced workpiece handling with up to two robots and up to two counter spindles Up to 28 tools, 24 of which can be driven Tool cartridge system with modular gear box to customize every position to your needs Driven tool spindles up to 13,800 rpm, up to 4.3 ft lband 1.2 hp(nominal) Hydraulic cylinder as standard solution, suitable for all clamping systems Possibility to change between collet clamping for short workpieces, guide bush for long workpieces and 3-jaws chuck for raw part machining Main spindles with direct drive torque motor water cooled up to 7,500 rpm Larger working area in a smaller foot-print Fast changeover between machine configurations Innovation is at hand with the newest FANUC 30i MULTISPRINT 36 for bar up to Ø1.4 in. - raw parts up to 2 in. without restrictions

| Machine Style(s): | Bar |

|---|---|

| Spindle Direction: | Horizontal |

| Operation Type: | CNC |

| CNC Type: | Fanuc 30i |

IS THIS YOUR COMPANY?

| Main Spindle Turning Diameter Max: | 2.000" |

|---|---|

| Main Spindle Turning Length Max: | 23.600" |

| Main Spindle Bar Diameter Max: | 1.400" |

| Tail Stock Quill And Body: | None |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Second Tool Carrier: | |||||||||

| Max Tools: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 41 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number Of Axes Opt: | 10 | ||||||||||||||||||

| Number Of Axes Opt 2: | 10 | ||||||||||||||||||

|

|||||||||||||||||||