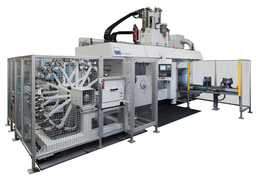

EMAG VM 9

The VM 9 vertical turning center is designed for the manufacture of individual parts and small production runs with a wide variety of parts. Depending on the desired interface (BMT or VDI), the tool turret features eight or twelve tool positions, which can also be equipped with driven tools to carry out drilling operations, for example. The integrated probe ensures process reliability and guaranteesconsistentlyhighworkpiecequality(firstpart=OK part).The VM 9 is thus extremely well equipped for a wide variety of production tasks

| Machine Style(s): | Chucker |

|---|---|

| Spindle Direction: | Vertical |

| Operation Type: | CNC |

| CNC Type: | Fanuc |

IS THIS YOUR COMPANY?

| Main Spindle Turning Diameter Max: | 17.500" |

|---|---|

| Main Spindle Chuck Diameter: | 17.500" |

| Main Spindle Max Swing: | 25.500 |

| Tail Stock Quill And Body: | None |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | Disc Type Turret | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 2 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number Of Axes Opt: | 3 | ||||||||||||||||||

| Number Of Axes Opt 2: | 3 | ||||||||||||||||||

|

|||||||||||||||||||