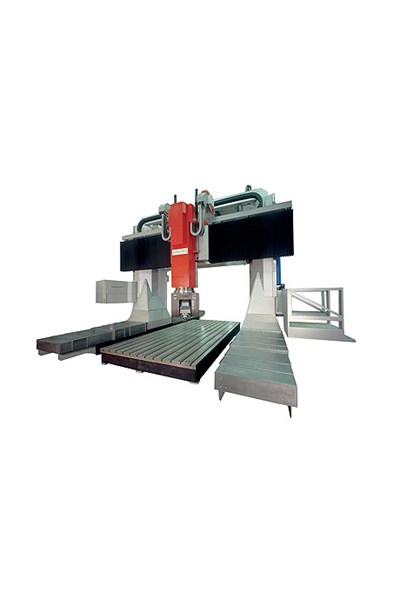

Matec HV 2000

matec hv 2000 Traveling Column Vertical/Horizontal Machining Center matec HV 2000 The travelling column machining centres matec HV 2000 and L 2000 are machines with superior equipment which are available with standard characteristics and options. From the matec modular component system options are available, which do not collide with the basic construction of the machines, e.g. mounted rotary tables with diameter 160/220 and 320 mm. Advantages of the machines are short delivery time and great price. matec L 2000 Fixed machine table for double work station and long-bed machining SK40 tool changer for tools according to DIN 69 871 Tool magazine with a capacity of 36 tool pockets, travelling in the X-axis (protected within the machine column) Machining area completely enclosed with electrically locked sliding doors Roller linear guides in all axes Acceleration of axes 0.19 sec. to 30 m/min Feed/rapid traverse speed 30 m/min with A.C. servomotors in all axes Motor spindle 16 kW Direct drive, oriented spindle mount Drilling capacity up to 60 mm into solid material in steel E 335 / AISI 1040 Milling capacity up to 500 cm3/min in steel E 335 / AISI 1040 Main spindle speed 20 - 9,000 min-1 Chip conveyor Only HV 2000: Swivel head � 90� for horizontal and vertical machining with Hirth serration catching in steps of 1�

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 3 |

| Operation Type: | CNC |

| CNC Brand: | Heidehain iTNC530 |

| CNC Brand Opt: | Siemens 840D |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 78.800(L) x 25.000(W) |

|---|

| Direction: | Combination |

|---|---|

| Taper: | SK40 |

| Taper Opt: | HSK 63A |

| Top RPM: | 12,000 |

| HP (30 min rating): | 20.00 |

| HP Opt: | 40.00 |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 36 |

| Num. Tools Opt: | 48 |

| Tool Change Time (sec): | 3.50 |

| Tool Change Chip Time (sec): | 5.50 |

| Pallet Changer Available: | Optional |

| Num. Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | None | ||||||||||||||||||

|

|||||||||||||||||||