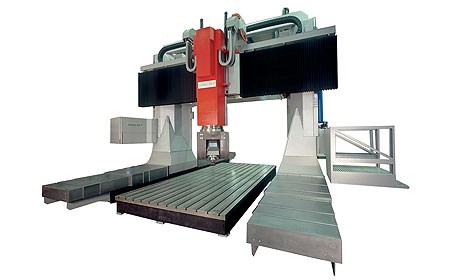

Matec 50 P

matec 50P Traveling Column Gantry Style Vertical/Horizontal Machining Center matec 50 P matec-50 P - for single and small series production The travelling gantry machining centre matec-50 P with 2-axis swivel head has been designed for single and series production of large-surface and voluminous parts for tool and mould making, structural steel engineering, and mechanical engineering. Main range of application is the machining of 3D-shapes in steel and aluminium, plates, welding and steel constructions. A newly designed plane tool changer with shuttle (optional) provides for a quick and safe tool change even in long travelling paths in the X-axis Travelling paths in X-axis 4,000 - 50,000 mm Stationary machine table Linear drives in X- and Y-axis 30 m/min (with heavy-load drive) Disc tool magazine travelling in X-axis Motor spindle with 9,000 rpm (water-cooled) Power S1 48 kW/S6 60 kW Torque S1 455 Nm/S6 575 kW 2-axis milling head with CNC motor spindle for multiple side machining Chip conveyor

| Machine Type: | Machining Center |

|---|---|

| Num. of Axes: | 5 |

| Operation Type: | CNC |

| CNC Brand: | Heidenhain |

| CNC Brand Opt: | Siemens 840D |

IS THIS YOUR COMPANY?

| Table Size L x W (in.): | 157.000(L) x 118.000(W) |

|---|---|

| Table Size L x W (in.) Opt: | 1968.000(L) x |

| Max Workpiece Weight (lbs): | 99,999 |

| Direction: | Combination |

|---|---|

| Taper: | SK50 |

| Taper Opt: | HSK 100 |

| Top RPM: | 9,000 |

| HP (30 min rating): | 80.00 |

| Tool Carrier: | ATC |

|---|---|

| Num. Tools: | 18 |

| Num. Tools Opt: | 200 |

| Tool Change Time (sec): | 10.00 |

| Tool Change Chip Time (sec): | 20.00 |

| Num. Axes: | 5 | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| U Axis: | None | ||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||