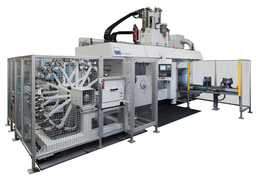

EMAG VL 2

Three axes + turret with up to twelve driven tools + automation. The basic VL 2 machine, a three-axis inverted vertical turning machine, has an eye-catching design. The lathe's basis is the machine body made of MINERALIT® polymer concrete. The working spindle is mounted on the front of the machine bod y on a compound slide, which completes movements in the X- and Z-axes. The turret is located below the working spindle and can hold up to twelve turning or driven tools. In addition, the VL 2 cnc turning machine can be equipped with a Y-axis in the turret. The lathes are also ideally designed for use in assembly line production, as the VL 2 turning machines can be linked with simple automation components, such as conveyors , flip-over units, and changers. Workpieces that can be machined with the lathe include flanges and gears. Here, combining the vertical lathes with other modular machines offers an efficient way to implement an assembly line for gears, f or example. The cnc turning performed by the VL 2 is complemented by a subsequent process on a VL 4 H for the tooth hobbing and the use of a VLC 100 C for chamfering.

| Machine Style(s): | Chucker |

|---|---|

| Spindle Direction: | Vertical |

| Operation Type: | CNC |

IS THIS YOUR COMPANY?

| Main Spindle Turning Diameter Max: | 4.000" |

|---|---|

| Main Spindle Turning Length Max: | 6.000" |

| Main Spindle Chuck Diameter: | 6.500" |

| Main Spindle Max Swing: | 8.500 |

| Tail Stock Quill And Body: | None |

| Num. Main Spindles: | 1 | |||||

|---|---|---|---|---|---|---|

| Main Spindle 1: |

|

|||||

| Main Spindle 2: |

|

| Primary Tool Carrier: | Turret | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Max Tools: |

|

||||||||

| Rotary Tool: |

|

||||||||

| Num. Simultaneous Cutting Tools: | 1 | ||||||||

| Secondary Mill/Drill Function: |

|

| Number Of Axes: | 3 | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|||||||||||||||||||