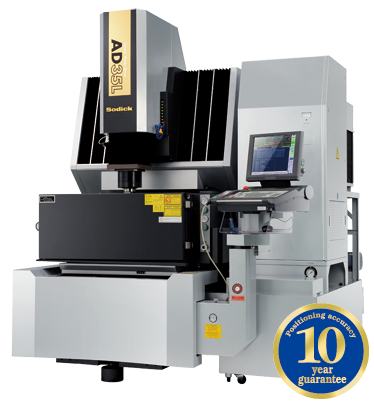

Sodick AD35L

Sodick's linear motor drive system on the Z-Axis is the ideal mechanism that semi-permanently sustains high speed axes-movements and instantaneous response. There is no mechanical contact within the linear motor drive system, resulting in stable machining accuracy, reliability and maintainability that can be sustained for years. The small footprint of the AD25L Sinker EDM is ideal for shops that are tight on space. The new LN controller will maximize the advantages of the linear motor drive system. "LN Assist" (standard) will enable even a beginner to operate the machine with ease. The power supply unit is designed to conserve energy. TheAD Seriesfeatures energy-saving designs and technologies. Compared to conventional EDMs, the Sodick Sinker EDM(Electrical Discharge Machine)Range can reduce average energy consumption by up to 60%. The "SVC" Circuit is the Sodick standard in the process of achieving *Zero electrode wear and high-quality surface finish. To create a uniform satin surface, the "SVC" enables a no-polish finish for micro and non-forms that are difficult to polish, by producing high grade surface finishes equaling shorter processes, improved quality and prolonged stability. The new electrical supply discharge circuit "Arc-less" enables no arc machining. It greatly reduces the machining time and number of electrodes used, leading to a dramatic reduction in cost and human errors. *Zero electrode wear is an electrode wear rate of less than .06%.

| Machine Type: | CNC Sinker |

|---|---|

| CNC Standard Model: | LN2 |

| Frame Type: | "C" |

| Submersible: | Standard |

IS THIS YOUR COMPANY?

| Table (L x D): | 23.620" x 15.740" |

|---|---|

| Worktank (L x D x H): | 38.390" x 21.850" x 13.780" |

| Auto Electrode Changer: | Optional |

|---|

| Number Of Axes: | 3 |

|---|---|

| X Axis Travel: | 13.780" |

| Y Axis Travel: | 9.840" |

| Z Axis Travel: | 10.630" |