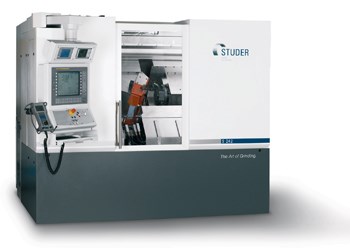

Studer S242

Studer Combination Hard Turning and Grinding Machine Studer S242 The combined machining system for hard turning and grinding enables rational hard-fine applications for both shaft and chuck work pieces. The Granitan® S103 inclined-bed machine base meets the following special requirements: - Good accessibility - Optimum chip discharge into the integrated chip conveyor - Effective vibration damping - Highest possible temperature stability The standard versions of the S 242 have either two or three center supports to accept the grinding or turning/milling tools. The distance between centers is 400 mm or 650 mm. Depending on the application, workpieces having a length of up to 1000 mm can be machined. The grinding tools have a diameter of 400 mm and the turning tool turret can accommodate up to 8 tools, including the optional live tooling. Features: Granitan® S103 mineral-cast machine base X1 axis: stroke 205 mm (8.5"); Vx 15 m/min; resolution 0,0001 mm X2 axis: stroke 205 mm (8.5"); Vx 15 m/min; resolution 0,0001 mm Z axis: stroke 800 mm (31.4"); Vz 25 m/min; resolution 0,0001 mm In-process gauging: length positioning, length and diameter measurements Full enclosure with sliding door Extensive range of accessories Easy programming with StuderWIN Programming software StuderGRIND for creating grinding and dressing programs on the PC Standardised interfaces for loader and peripheral devices Grinding spindle: 6.8 kW, Vs 50 m/s; Position 0 or 25 deg; automatic balancing, grinding wheel diameter 400 x 50/63 mm Rotating turret: 8 tool positions Option: up to 4 driven tools for drilling and milling Workhead: synchronous motor spindle 5.5 kW; 3500 rpm; adapter for center MT4; Chuck dia. 130/160 mm; chuck fixture DIN 55026 Tailstock slide Stroke 450 mm (17.7"); resolution 0,001 mm; V 15 m/min Workpiece fixture standard: barrel dia. 60 mm; stroke 10 mm; adapter for centres MT4; centering pressure manually adjustable Option: synchronous motor spindle 2.1 kW; 3500 rpm; adapter for centres MT3; programmable clamping force

| Machine Operation: | CNC |

|---|---|

| Grinder Type: | Cylindrical-OD, Special Purpose |

| CNC Model: | Fanuc 310i-A |

| CNC Model Opt: | Siemens 840D |

IS THIS YOUR COMPANY?

| Grinding Length: | 15.700" 398.780mm |

|---|---|

| Grinding Depth: | 8.700" 220.000mm |

| Grinding Depth Opt: | 4.720" 120.000mm |

| OD Max Grinding Diameter(s): | 7.100" 180.340mm |

| ID Max Grinding Diameter(s): | 4.700" 120.000mm |

| Grinding Wheel: |

|

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wheel Head: |

|

||||||||||||

| Workhead: |

|

| Longitudinal: | 31.400" 797.560mm |

|---|---|

| Cross: | 8.500" 215.900mm |